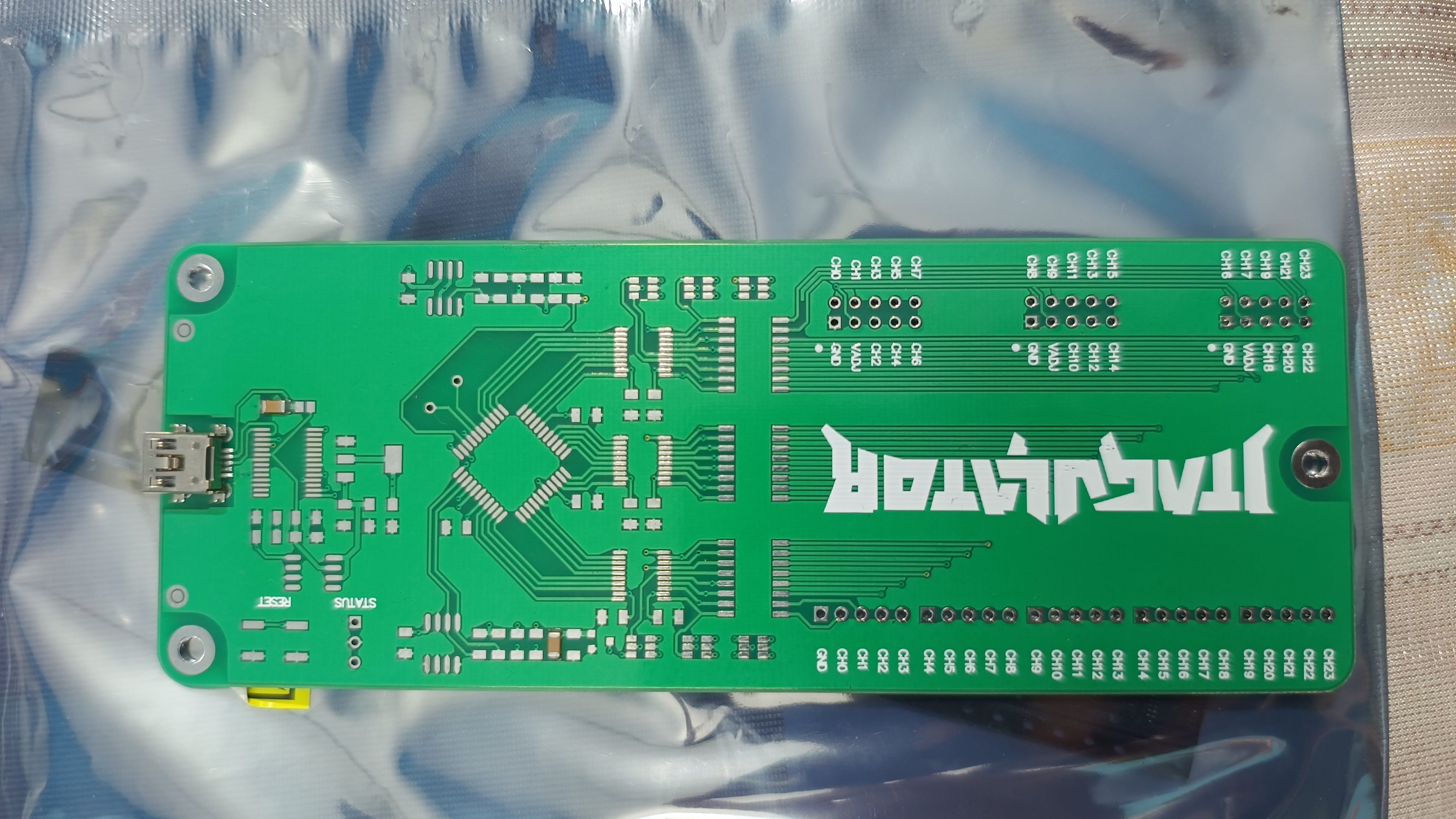

Hello, everyone! Welcome to this blog where we delve into the motivation and process of building a JTAGulator, an invaluable tool for test engineers, developers, and hackers alike. If you’re looking to identify on-chip debugging interfaces such as JTAG, UART, or SWD, this blog is for you!

Note: Price mentioned includes India import and custom taxes; we ordered in bulk.

The idea for this blog came when we realized how challenging it was to source a JTAGulator within India. JTAGulator, an open-source tool by Joey Grand from Grand Idea Studio, is essential for identifying various interfaces on embedded devices.

The tool lets you configure aspects like input-output voltage, making it versatile. Despite being launched at DEFCON 21 in 2013, it remains a reliable and popular tool among hackers.

Given its rarity in stock, we decided to build our own!

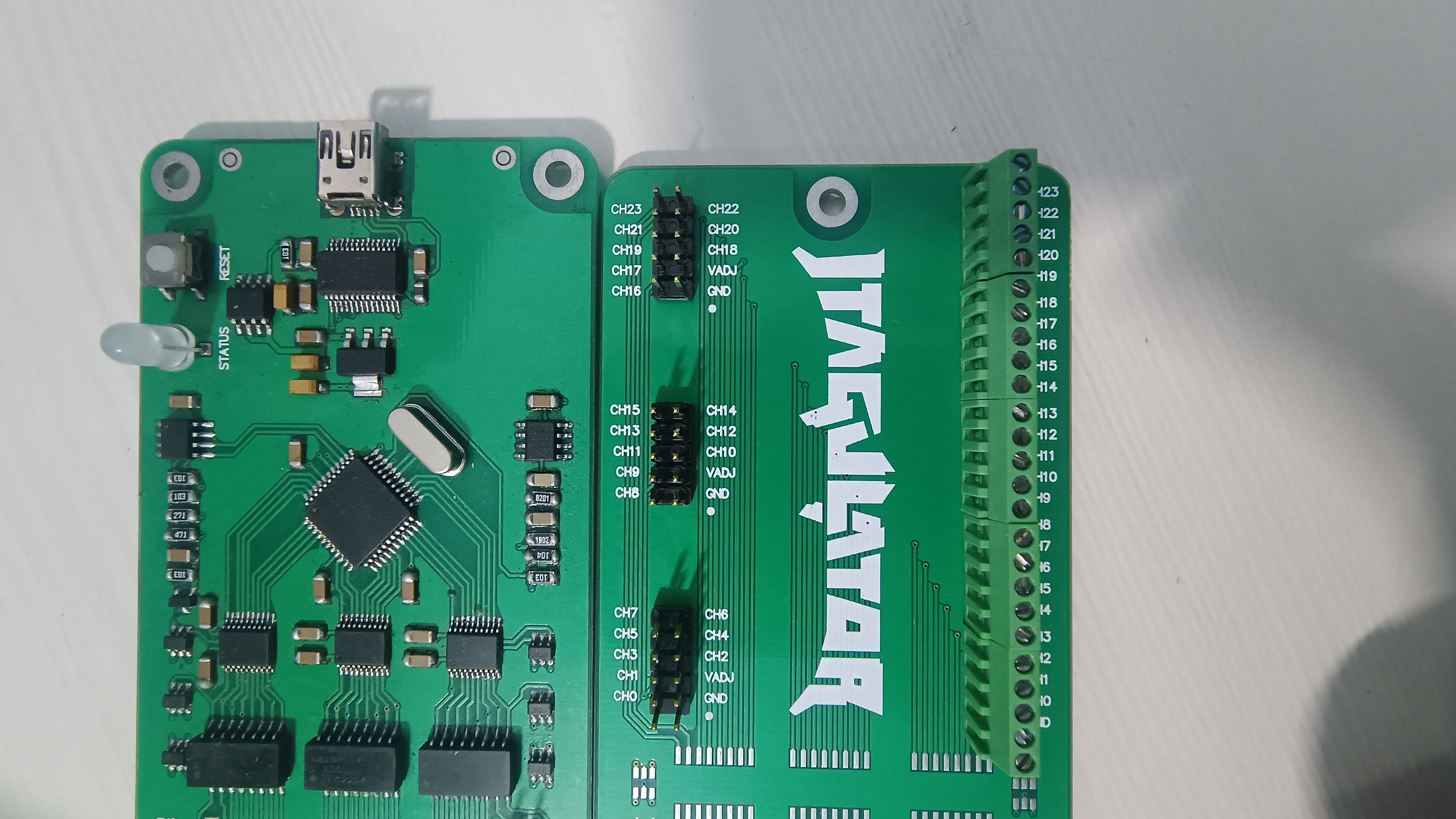

We started by downloading the Gerber file from Grand Idea Studio’s website. As per the Creative Commons Attribution 3.0 Licence, full credit goes to Joey Grand and Grand Idea Studio.

We uploaded the Gerber file to a local PCB manufacturer.

Cost: ~350 INR (~4.5 USD) per PCB.

Download: JTAGulator Gerber Files

The Bill of Materials (BOM), available on Grand Idea Studio’s site, includes:

Tip: Some countries enforce import regulations; prepare for customs clearance accordingly.

With the PCB and components ready, we used the following tools for assembly:

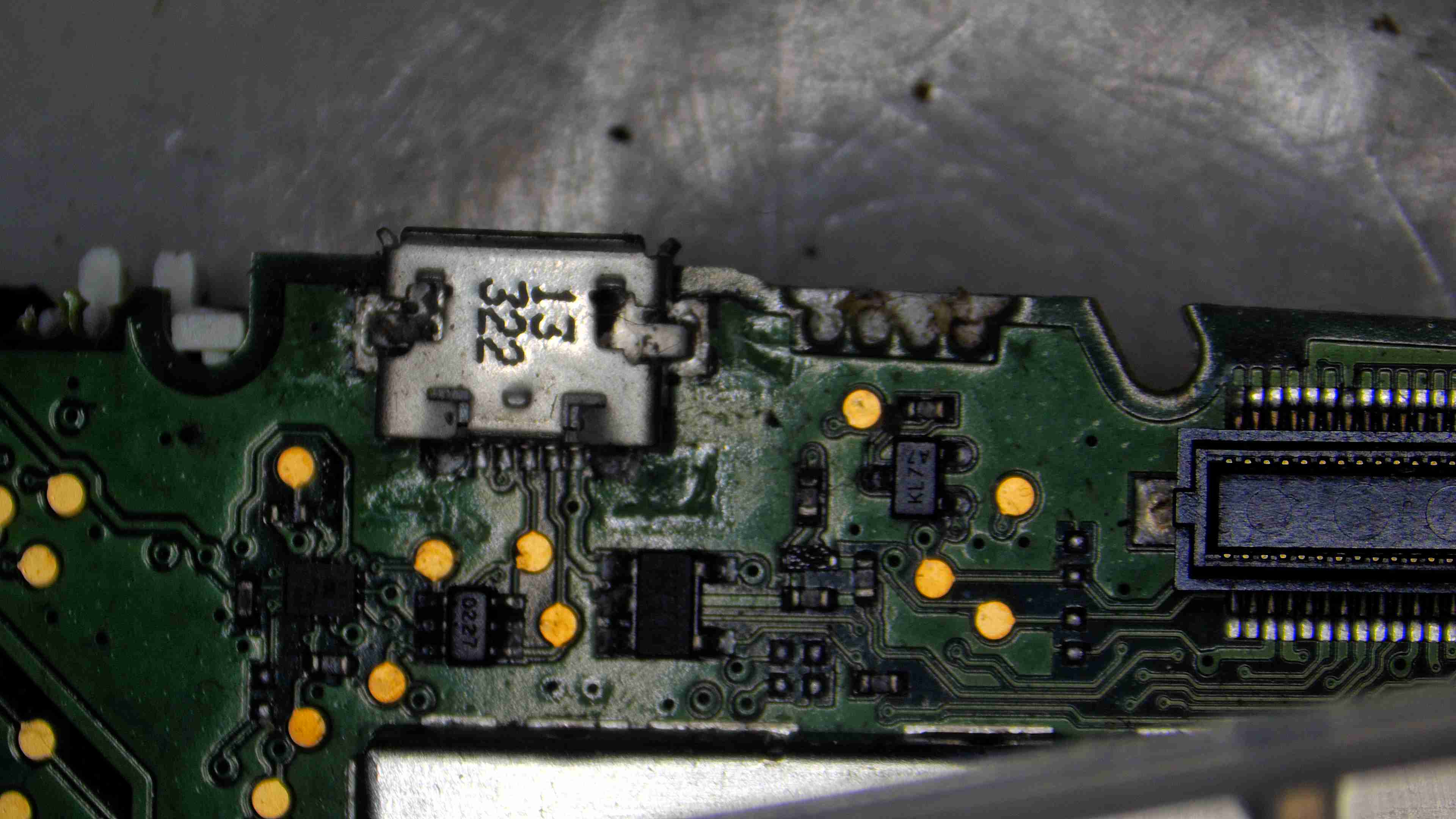

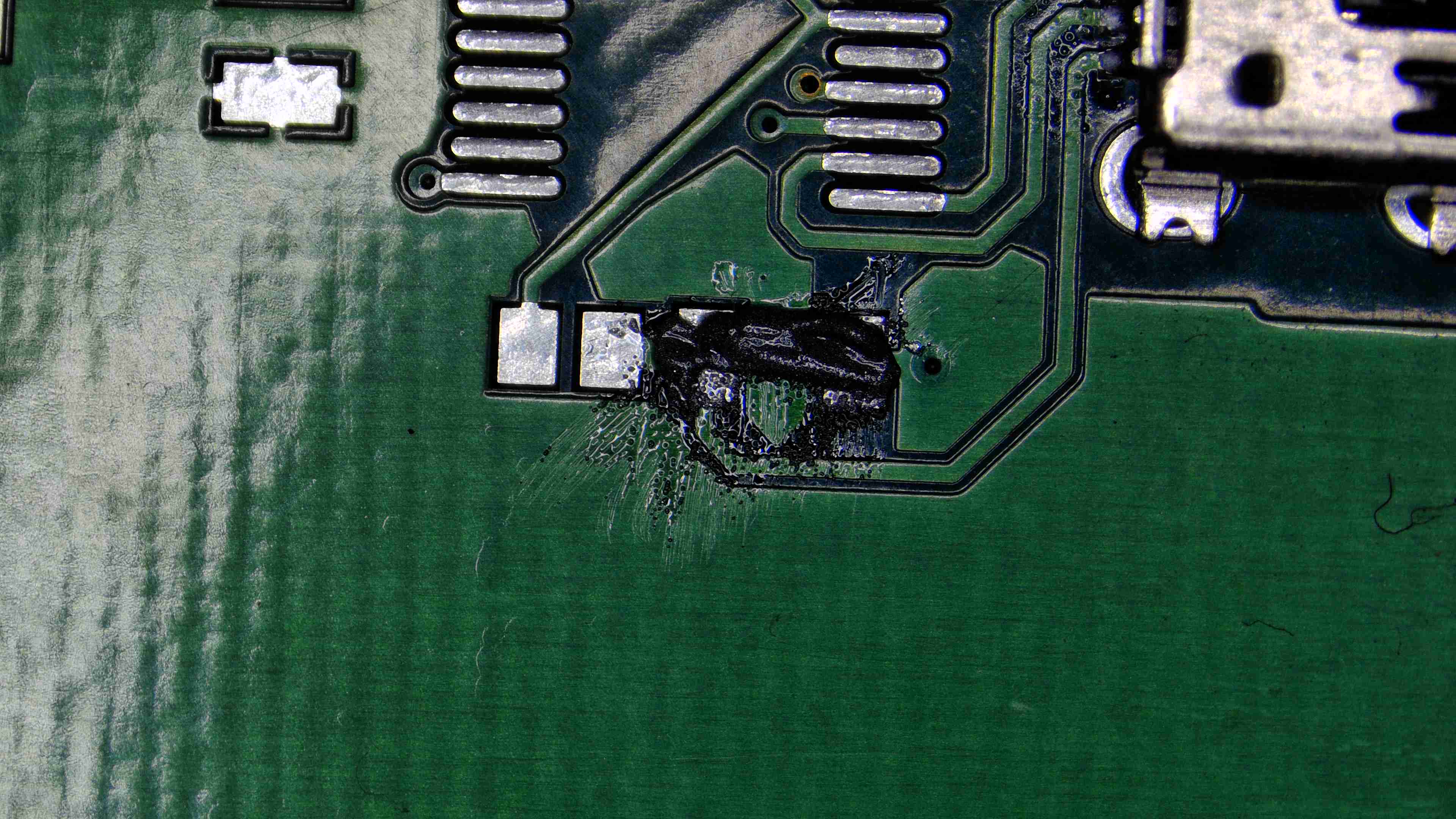

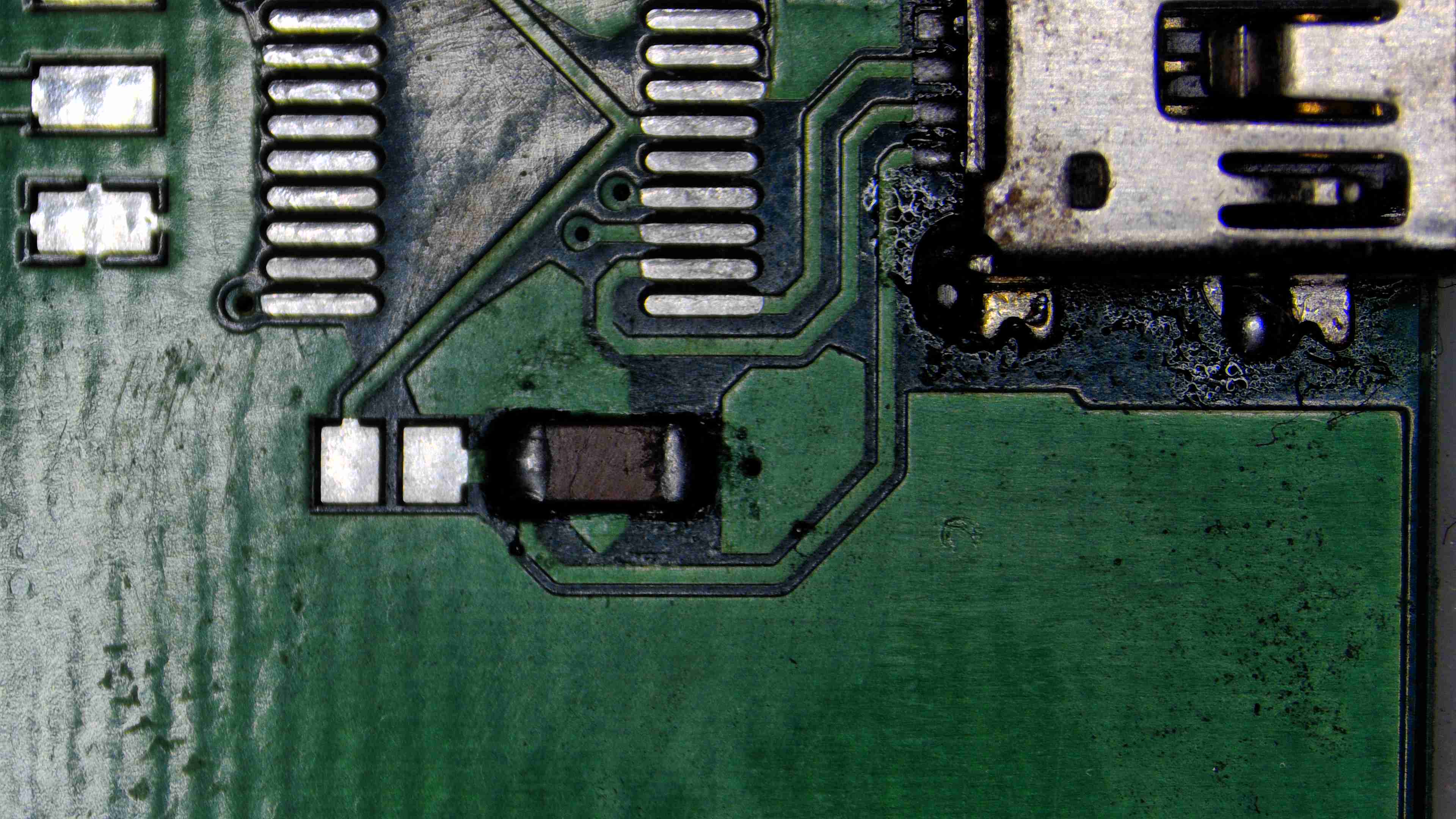

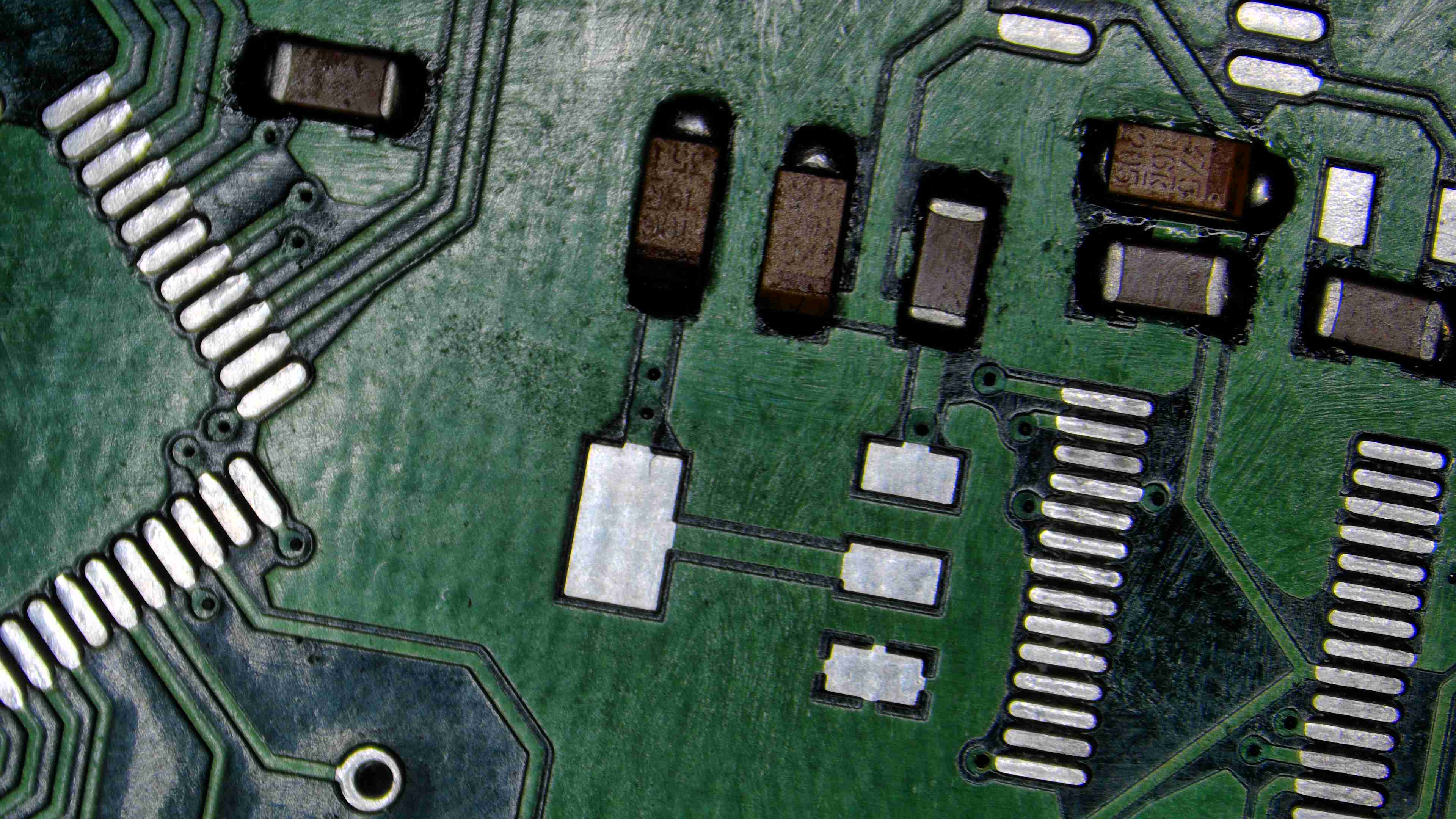

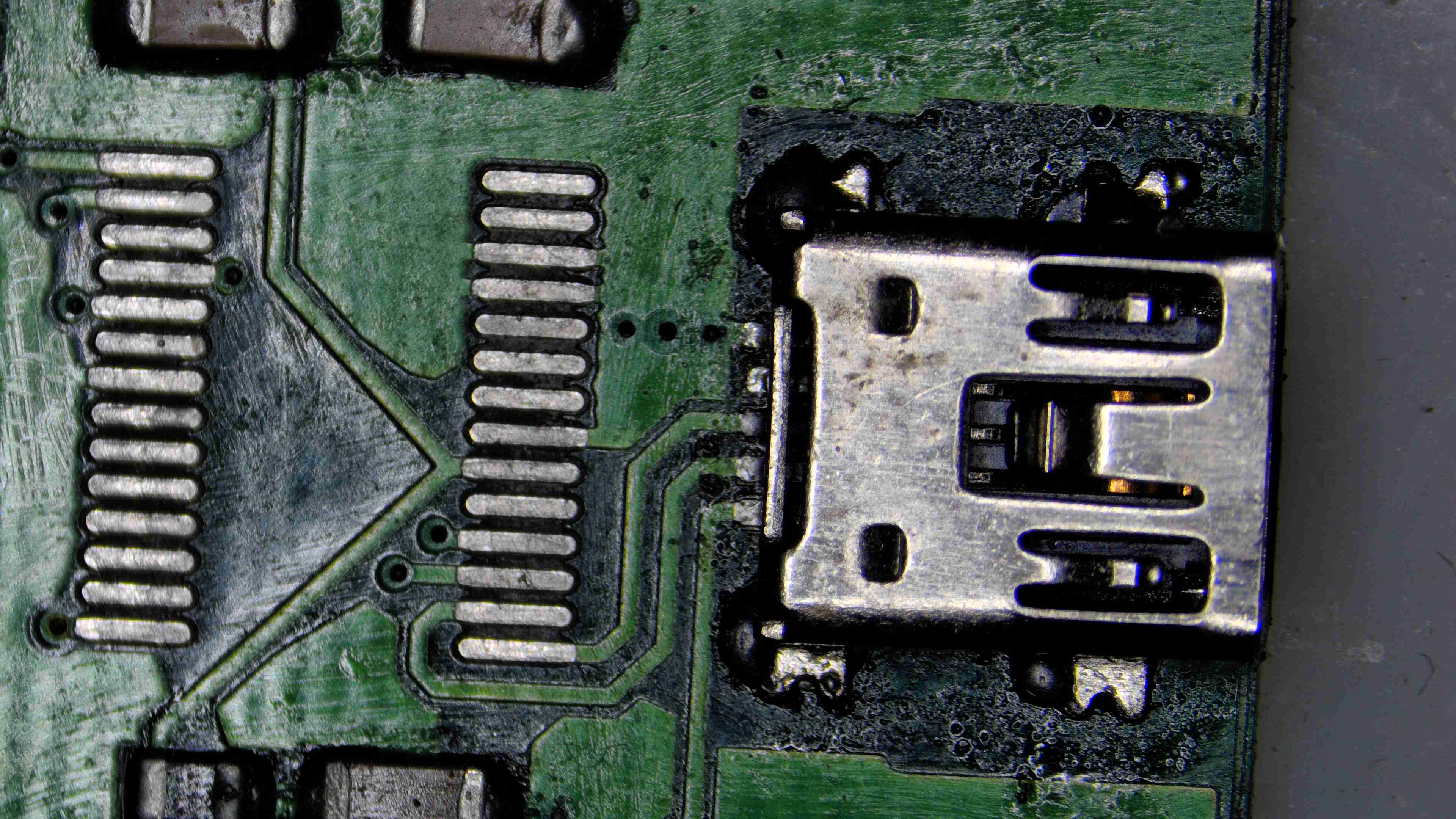

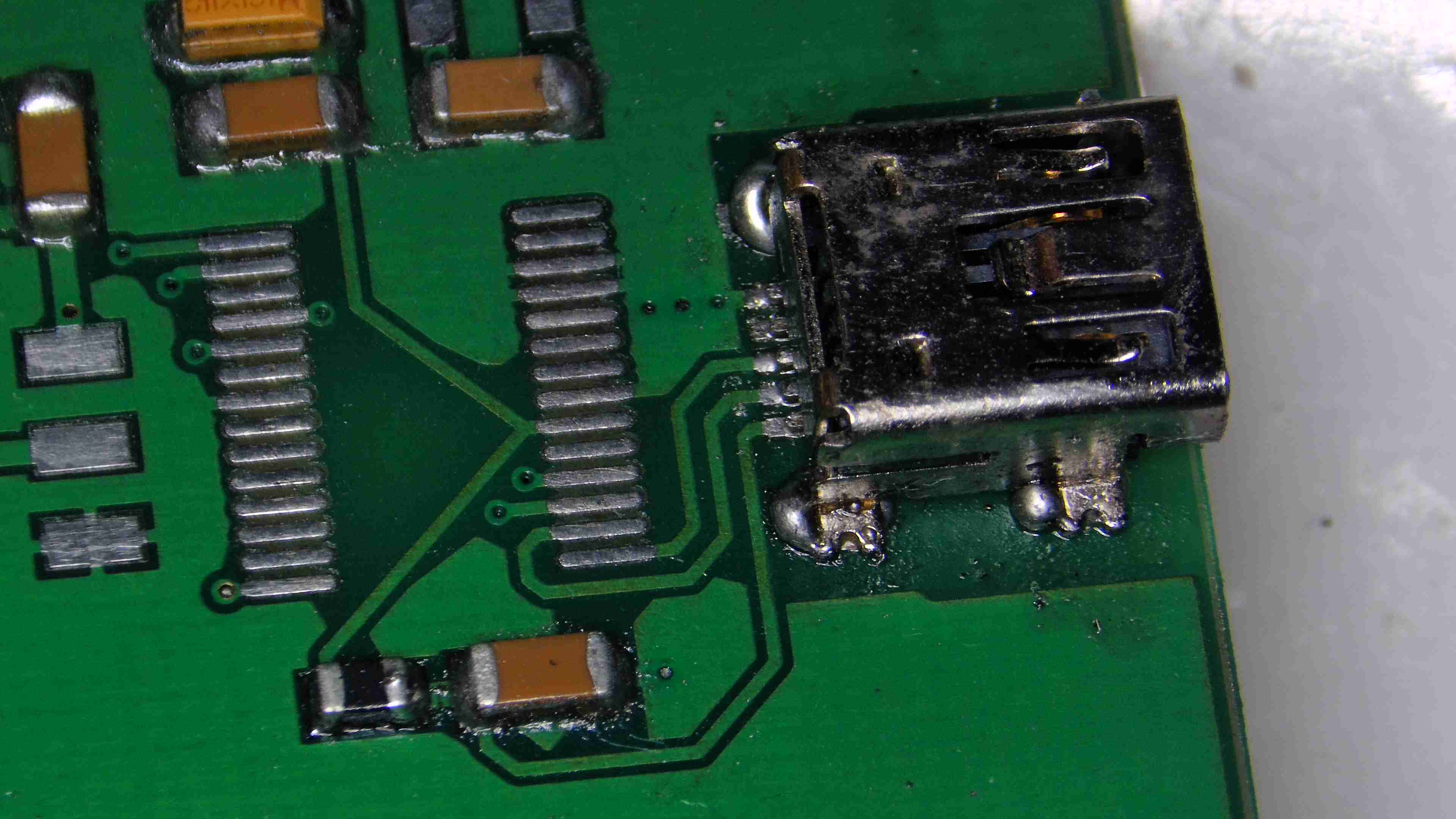

Placement of SMD components, especially those with polarity (e.g., tantalum capacitors), required precision. Capacitors, resistors, diodes, and ICs were placed as per the BOM.

After placement, we:

Common issue: Shorts around ICs can prevent USB detection.

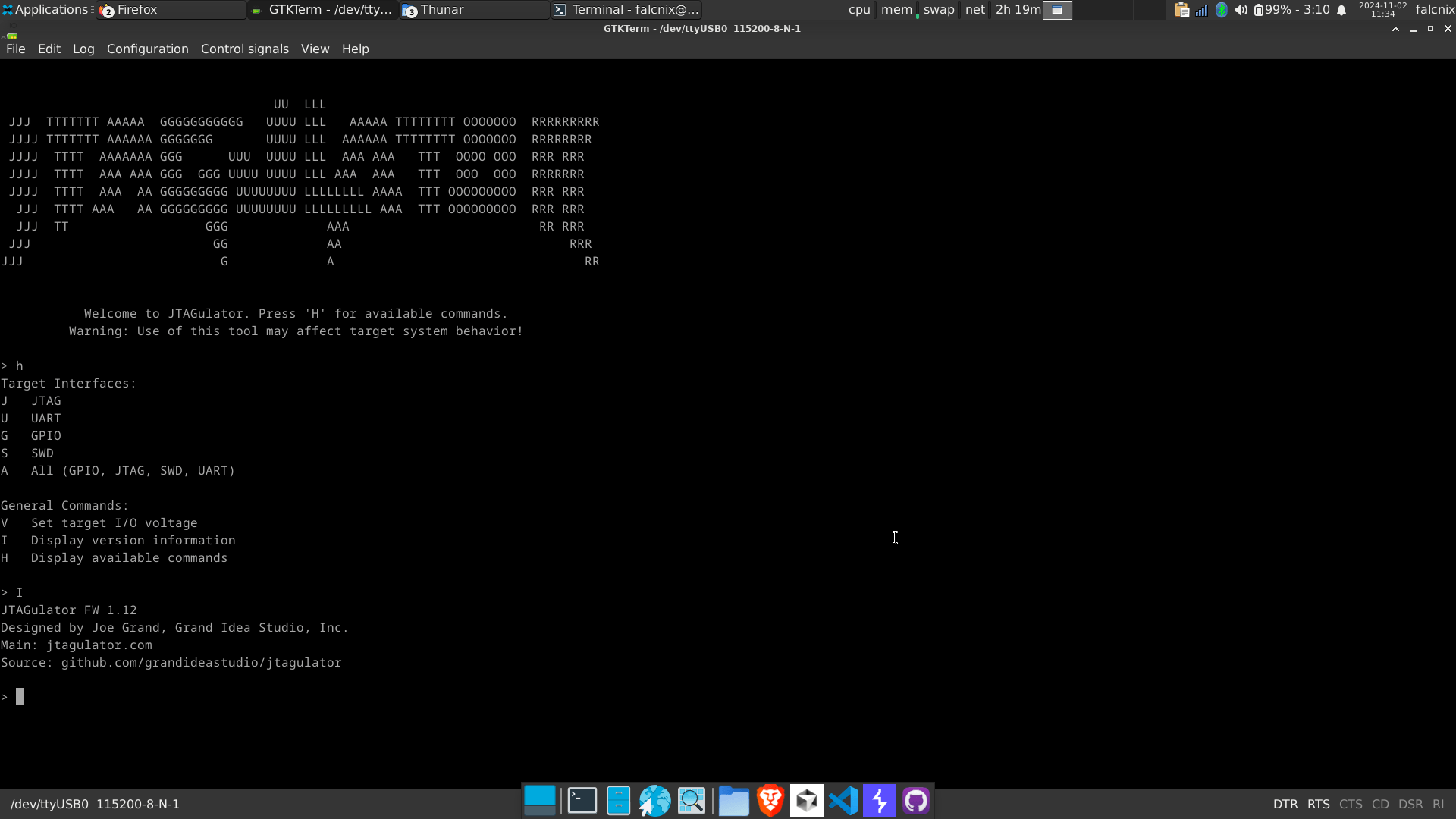

We followed the test procedure from Grand Idea Studio.

We connected to the JTAGulator via serial console (e.g., GTKTerm) at 115200 baud.

On success, the device displays a welcome message and the LED turns green.

Download Propeller Tool v1.3.2

| Component | Cost (INR) |

|---|---|

| PCB | 350 |

| Components (imported) | ~4800 |

| Assembly Tools/Extras | ~350 |

| Total | ~5500 INR (~66 USD) |

With patience and precision, building a JTAGulator can be rewarding and cost-effective.

This DIY approach not only saves money but offers deep insight into hardware debugging.

Embrace the hacker’s way - bruteforce those pins and own the board.

Happy Hacking! 🎉